Flexo printer slotter die cutter stacker

Flute laminator machine

Folder gluer machine

Die cutter machine

Carton Stitchier machine

3,5,7 ply corrugated cardboard production line

Mill Roll Stand

Single facer machine

Sheet cutter

Paper Edge Protector Corner Machine

Thin blade slitter scorer machine

Slotter machine

Automatic feeder machine

Film Laminating Machine

Touch Line machine

High Speed Partition Machine

Strappling Machine

Automatic Pallet Wrapping Machine

Paper Tube Core Making Machine

Min box folder gluer

Egg Tray Making Machine

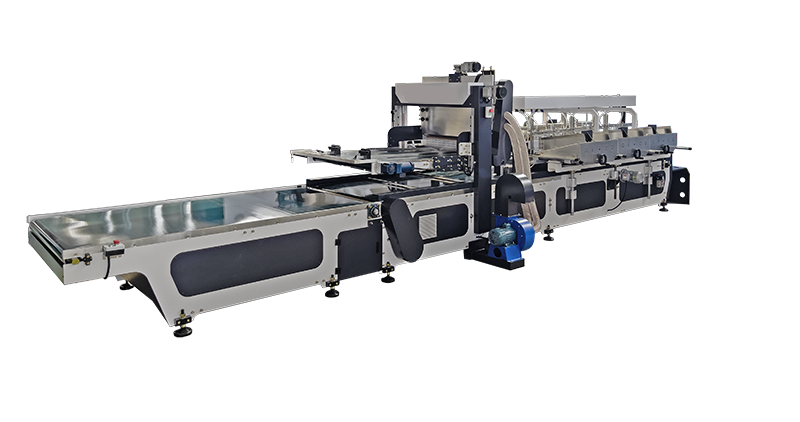

Full automatic high speed partition assemble machine

| 序号S/N | 名称 Components Name | 数量 Qty | 备注 Remarks |

| 1 | 自动插格机 Auto Partition Assembling Machine | 1台 1unit | 格板输出方式:双工位;格板组合形式:十字交叉 Assembly method: Double Stations Cross-Assembling |

| 2 | 输纸部 Feeding Unit | 1台 1 unit | |

| 3 | 气动系统 Pneumatic System | 1套 1 set | 气源客户自备 Customer provided air compressor |

| 4 | 电器系统 Electric Components | 1套 1 set | PLC、人机界面、伺服控制 PLC, HMI, Servo control |

配置单 Components List

| 名称 | Name | 品牌Brand |

| 伺服电机 | Servo Motor | 安川 Yaskawa, Japan |

| PLC | PLC | 施耐德Schneider |

| 伺服驱动器 | Servo Driver | 安川 Yaskawa, Japan |

| 变频器 | Inverter | 施耐德Schneider |

| 触摸屏 | Touch Screen | 施耐德Schneider |

| 交流接触器 | AC Contactor | 施耐德Schneider |

| 风机 | Draught fan | 九洲普惠Popula |

| 真空泵 | Vacuum pump | EUROVAC, Taiwan |

| 接近开关 | Proximity switch | SICK, South Korea |

| 牵引辊电机 | Roller motor | 上海德东Dedong Electric, China |

| 插板气缸 | Cylinder | 亚德客Airtac, Taiwan |

| 电磁阀 | Solenoid valve | 亚德客AirTAC, Taiwan |

| 气源处理元件 | Clean air components | 亚德客AirTAC, Taiwan |

| 油水分离器 | Oil-water separator | 神驰SNS, China |

结构特点

结构特点Structure Character

*纵、横向同时给纸进行十字交叉插格

* Lengthways & transverse same time cross assembling

*适合各种纸箱隔板、格挡的自动化插编

* suit for each kind clapboard, baffle/block board automatic assembly

*取代传统手工操作模式,双工位出纸

*Instead traditional manual working, double-station output in same time

型号 Model | 外形尺寸(长×宽×高 m ) Dimension (L x W x H m) | 功率 (kw) Total power |

| CGJ450-3L | 7.3*2.0*1.9 | 6.8 |

技术参数 Technology Parameter

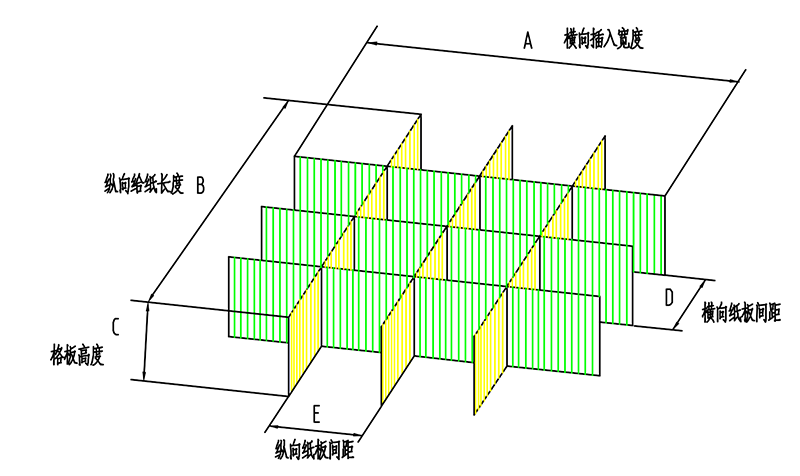

格板参数表 Clapboard List

CGJ450-3L参数表 Parameter List

| 称/Name | 单位/Unit | 数据/Data |

| 横向插入宽度/ Transverse assembly width : A | mm | 双工位出纸80~420 Double station 80-420 |

| 单工位出纸80~900 Single station 80-900 | ||

| 纵向给纸长度/ Lengthways length: B | mm | 210~450 |

| 格板高度/Clapboard Height: C | mm | 70~300 |

| 横向纸板间距/ Transverse clapboard distance: D | mm | 20~400 |

| 纵向纸板间距/ Lengthways clapboard distance: E | mm | 45-800 |

| 纵向格板数量/ Lengthways sheets quantity | 片/sheets | 1-6 |

| 横向格板数量/ Horizontal clapboard quantity | 片/sheets | 1-21 |

| 纸板插口宽度/ Carton inserting mouth width:F | mm | >纸板厚度 >board thickness |

| 纸板厚度 /Carton thickness: G | mm | 1.5~8mm |