Flexo printer slotter die cutter stacker

Flute laminator machine

Folder gluer machine

Die cutter machine

Carton Stitchier machine

3,5,7 ply corrugated cardboard production line

Mill Roll Stand

Single facer machine

Sheet cutter

Paper Edge Protector Corner Machine

Thin blade slitter scorer machine

Slotter machine

Automatic feeder machine

Film Laminating Machine

Touch Line machine

High Speed Partition Machine

Strappling Machine

Automatic Pallet Wrapping Machine

Paper Tube Core Making Machine

Min box folder gluer

Egg Tray Making Machine

Full automatic Top plater pallet wrapping machine 1650F-CS pneumatic Type

1.Machine introduction

Fit motorised top plate based on T1650F. This machine is widely suitable for tall and unstable good, top plate provides a press to the top of load and ensure it safety packing. This machine is widely suitable for tall unstable good, top plate provides a press to the top of load and ensure it safety packing.

2.Technicial parameter

| Wrapping size(L*W) | (500~1200)×(500~1100)mm |

| Packing Height | 1.2-2.4mm |

| Turntable diameter | 1650mm |

| Turntable Height | 85 mm |

| Turntable weight capacity | 2000kg |

| Turntable speed | 0-12rpm |

| Top pressure | 20 kg |

| Electrics | 380V 50HZ |

| Power | 1.5kw |

| Machine dimensions (mm) | 2650(L)×1650(W)×2800(H) |

| Packing efficiency | 20-40 loads/hour base on load |

| Top Plate Device | Adopt Pneumatic Direct Transmit Orbit Top Plate |

| Penumatic Systerm Pressure(mpa) | 0.6-1.0 |

| Penumatic Systerm Consumption | 1000ml/min |

| Machine weight | 800kg |

3、Material usage:

Machine is using a standard type of stretch film packaging material for creating a hard to tear,resistance,waterproof cover over the baggage.Thefilmisrecyclable.Specification:width:500mm,thickness:20-25 microns,length:1500meters,weight: max:16kg,stretchable,one side sticky,transparent or colored.

4.Function of the machine:

1.Control System

PLC control

Photo-eye auto-height sensing pallet height

Separate top ,bottom & up-down Wrap Counter options

Overwrap time is up to create an overwrap

Reinforce wrap times is set to better secure 2 loads placed on top of each other

Film Tension Control adjustment on the panel

Separate start, pause and emergency stop buttons

Power indicator

Manual carriage up/down

Variable Turntable Speed

Carriage up/down speed control

Manual/automatic exchangeable

2.Turntable

1650mm Diameter Structural steel plate

85mm Height floor to top of turntable

3.Turntable drive

0-12rpm variable turntable speed by frequency changer

Position turntable alignment

Soft start

4.Film carriage

Powered pre-stretch system up to 250% to min film consumption

Film delivery variable speed by separate DC Drive Motor

Electronic film tension control adjustment on panel

Film dancer-bar with variable speed output

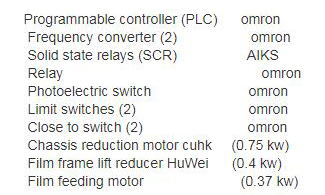

5.The main electrical configuration

6. Film carriage Drive

Heavy duty double-chain carriage lift, calm and safety

Film carriage variable speed by frequency changer