Flexo printer slotter die cutter stacker

Flute laminator machine

Folder gluer machine

Die cutter machine

Carton Stitchier machine

3,5,7 ply corrugated cardboard production line

Mill Roll Stand

Single facer machine

Sheet cutter

Paper Edge Protector Corner Machine

Thin blade slitter scorer machine

Slotter machine

Automatic feeder machine

Film Laminating Machine

Touch Line machine

High Speed Partition Machine

Strappling Machine

Automatic Pallet Wrapping Machine

Paper Tube Core Making Machine

Min box folder gluer

Egg Tray Making Machine

Semi Automatic press type Folder Gluer with lock bottom machine

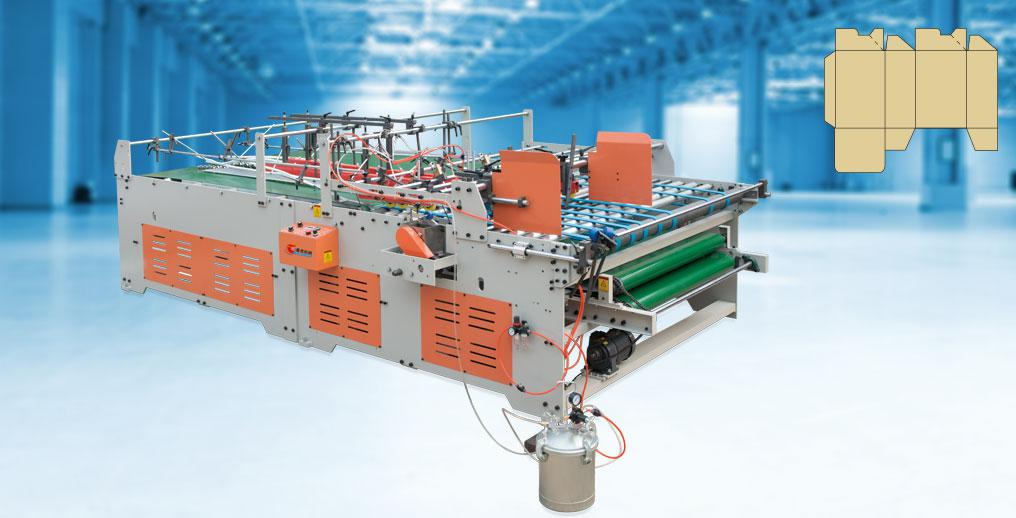

Introduction:

JLsemi automatic pressing type gluing machine, in recent years, small and medium-sized orders, according to user needs of heterosexual carton, carton production of the latest research and development of new environmental protection equipment. Its small size to cover an area of little, operation is simple and does not require experience, very suitable for small batch production and varieties of replacement; wide application scope, ordinary cardboard boxes, special-shaped box sheet forming adhesive, double carton and earth covered carton; save the glue, the glue quantity is only equivalent to manual gluing 1 / 3; artificial equipment, a maximum speed of 40 M / min, efficiency is the manual operation of the 3-4 times; bonding firm, clean overflow of glue, patents are polished to remove UV optical coating, or coating plastic layer, improve the glue stick relay, lifting the carton plant in some seasonal carton easy open problem. This machine adopts manual folding, improves the efficiency and is suitable for automatic processing of the indentation is not good, special sex and the paper surface with fenestration products.

The parts of machine :

paper feeding table, a conveying device, coating device, conveying device, in the middle of the pressing device, the electrical control device.

The product structurer

JL pressing type semi automatic box gluing machine using sophisticated processing technology and high-quality steel fabrication, mechanical efficiency per minute 40-60 sheet. Using intelligent digital counter, convenient and quick to improve production efficiency.

1. Coating part made of high-quality stainless steel for the plastic slot, and major components, never rust coating, corrosion resistance to a wide variety of glue. Optional models for pasting wheel configuration, can meet the needs of different products.

2. The pressing part using high strength conveyor band, on the pressing carton, carton conveyor to one end, have to ensure no damage of paper box quality.

Fittings choose:

1. The machine choose 380 V (440V) , power 0.8 KW, energy saving, high efficiency.

2. Choose imported Italian belt loop seamless docking belt.

3. Bearing choose the international famous brand TR bearing.

4. Spiral wire rod, ball screw, nut are chosen for 45 # steel, high quality and quenching process processing.

5. Copper set (ZQSn6-6-3) with, drops of oil lubrication, wear-resisting durable.

6. The whole machine are chosen for Taiwan's motor's, low noise, environmental protection, energy saving and low energy consumption.

The main technical parameters

Main Specifications | |||

Model | 1100 | 1500 | 1800 |

Max size | 1100x800mm | 1500x800mm | 1800x800mm |

Min size | 450x300mm | 450x300mm | 450x300mm |

Power | 0.8kw | 0.8kw | 0.8kw |

| speed | 40m/min | 40m/min | 40m/min |

Dimensions | 4500×2100×1500 | 4500×2500×1500 | 4500×2800×1500 |